We are blessed to collaborate directly with those who ride our craft. Their creative input informs our process both in terms of board design and aesthetic. We've decided to add a bit more documentation about the behind-the-scenes of our board making process to help educate readers about how board come to be; why they look they look and the conversations and mock-ups that go into creating our craft. We hope this provides a new perspective for current projects and inspires future collaborations.

Featured board: 6'0" Plankton

With only weeks to go before our wedding, I figured I should do whatever I could to prevent bridal flight. I decided to make Sarah a fresh shortboard to accommodate her growing proficiency with it (shortboarding). We decided on the dimensions (6'0" x 19 1/2" x 2 3/8") and the outline- modified Plankton as well as some fancy fabric inlays to give it character. Off to the shaping bay!

For bottom contours, we chose the new standard in shortboard technology- single through the mid, double under the fins, vee at the tail block..

Mapping out the outline

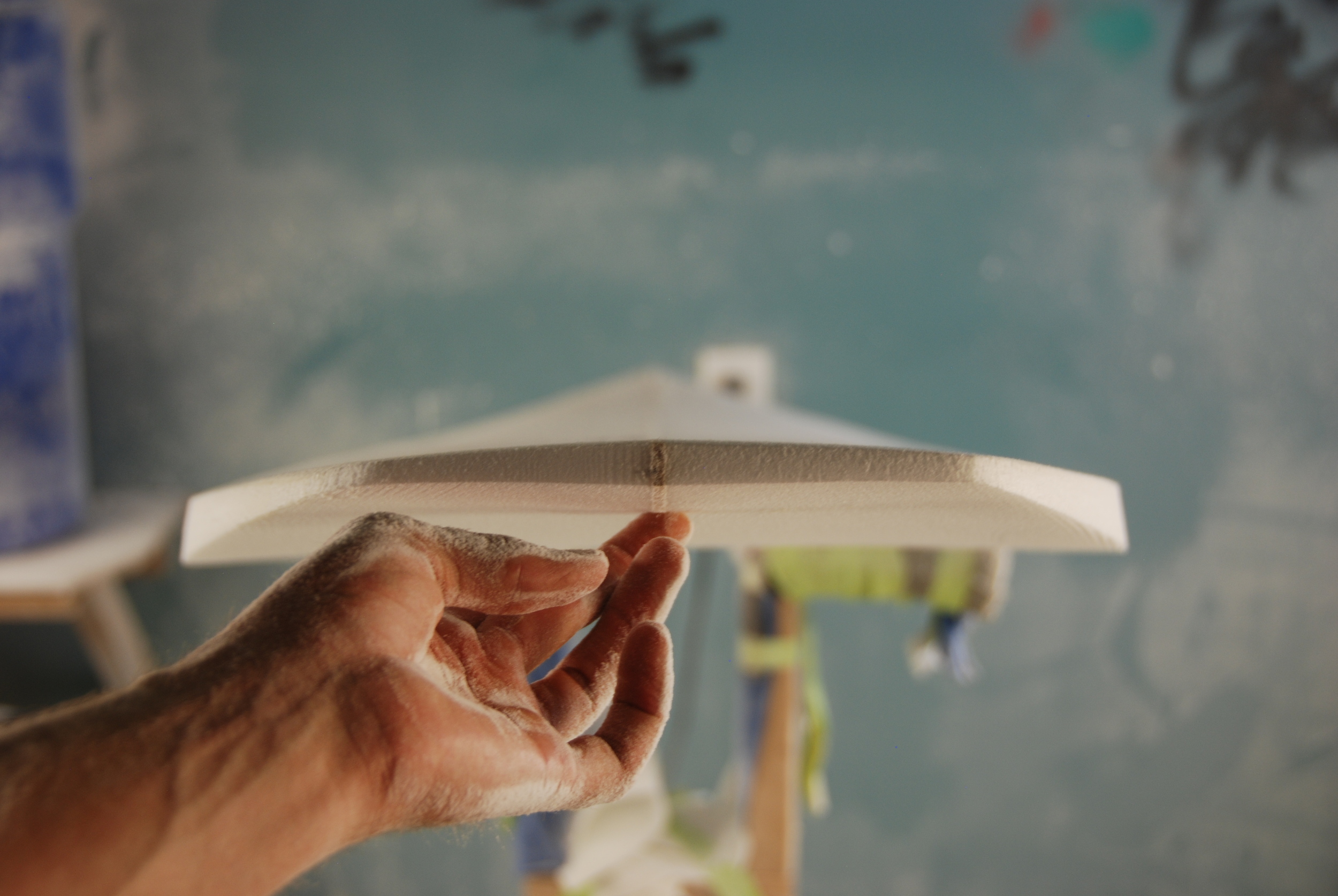

A few pictures of the shaped board. Fin boxes are sometimes routed out at this stage but, for this board, we waited until after lamination.

And now for some fabric magic.

Taped off the area where inlay #1 would go.

Add fabric & resin!

Remove masking paper/tape

Time for the deck inlay-

More fabric, more resin

Time for some actual fiberglass! Single 6oz layer on the bottom and 1 x 4oz + 1 x 6oz layer on the deck. Had to route out those fin boxes and laminate a few logos in as well. Here are a bunch of pictures of the finished produce. The board is not actually glossed- I just snapped them right after I had finished wetsanding, but man that water does help bring out the fabric pattern!

She looks like quite the happy customer!